Multi Head Weigher Filler Machine

Multi-Head Weigher Filler Machine for High-Speed, Precise, and Versatile Packaging Solutions

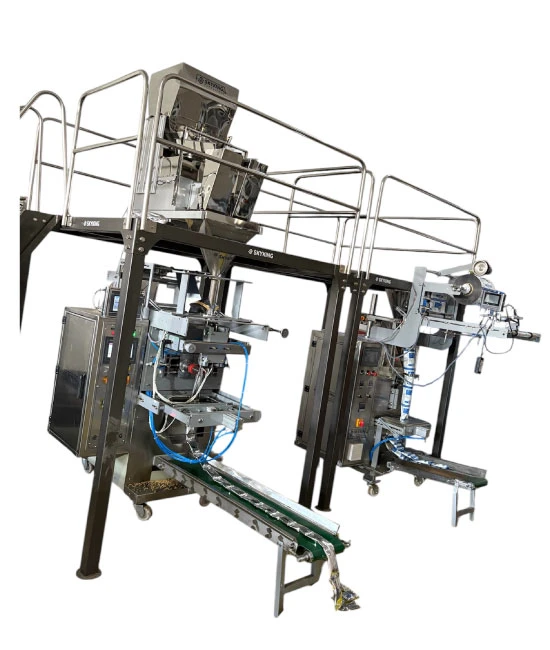

The Multi-Head Weigher Filler Machine is an advanced packaging solution engineered for high-speed and precise filling operations.

Featuring multiple weighing heads, it ensures simultaneous and accurate distribution of products, significantly boosting productivity.

Its robust stainless-steel construction adheres to strict hygiene standards, making it ideal for industries such as food, pharmaceuticals, and cosmetics.

The intelligent weighing system reduces wastage, providing exceptional accuracy with every batch.

The machine is compatible with a variety of materials, including granules, powders, and small solids, offering unmatched versatility.

Its intuitive control panel simplifies operation, while customizable settings accommodate different product types and packaging sizes.

Compact in design, it seamlessly integrates into production lines, optimizing space and efficiency.

Multi Head Weigher Filler Machine

Multi-Head Weigher Filler Machine for High-Speed, Precise, and Versatile Packaging Solutions

The Multi-Head Weigher Filler Machine is an advanced packaging solution engineered for high-speed and precise filling operations.

Featuring multiple weighing heads, it ensures simultaneous and accurate distribution of products, significantly boosting productivity.

Its robust stainless-steel construction adheres to strict hygiene standards, making it ideal for industries such as food, pharmaceuticals, and cosmetics.

The intelligent weighing system reduces wastage, providing exceptional accuracy with every batch.

The machine is compatible with a variety of materials, including granules, powders, and small solids, offering unmatched versatility.

Its intuitive control panel simplifies operation, while customizable settings accommodate different product types and packaging sizes.

Compact in design, it seamlessly integrates into production lines, optimizing space and efficiency.

Product Specification

Filling Type: Multi-Head Weighing System (Available in 10, 12, 14, or 20 heads depending on application)

Filling Range: 10 g to 5 kg (adjustable with programming and hardware configurations)

Filling Speed:

10 Heads: Up to 60-120 pouch per minutes

14 Heads: Up to 100-160 pouch per minutes

20 Heads: Up to 200 pouch per minutes

Accuracy: ±0.1-0.5% (depending on product type and calibration)

Weighing Mechanism:

Individual load cells for each head

Digital combination technology for optimal weight accuracy

Hopper Capacity: 1-5 liters per head (customizable)

Control System:

PLC with HMI (Touchscreen Interface)

Multi-language support

100+ programmable recipes for different product types

Power Supply: 220V/380V, 50/60 Hz, 3-phase

Power Consumption: Approx. 3-10 kW (varies with model and features)

Air Pressure Requirement: 6-8 Bar

Machine Dimensions: L x W x H (depends on model; approx. 1400 mm x 1200 mm x 1800 mm)

Weight: Approx. 800-1500 kg (depending on configuration)

Temperature Control (Optional): Adjustable up to 300°C for sealing integration

Noise Level: Below 70 dB