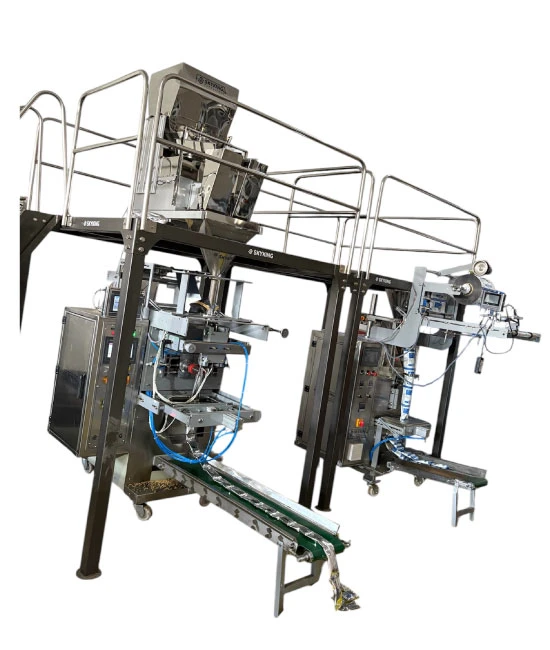

Half Pneumatic Auger Filler Machine

Half Pneumatic Auger Filler Machine for Semi-Automatic Accurate Filling Solutions

The Half Pneumatic Auger Filler Machine is a reliable and cost-effective solution for semi-automatic filling operations.

Designed for precision, it handles a wide range of materials, including powders, granules, and semi-solids, making it ideal for industries such as food, pharmaceuticals, and chemicals.

The pneumatic system ensures smooth and consistent operation, reducing manual effort while maintaining accuracy.

Its stainless-steel construction guarantees durability and hygiene compliance, suitable for sensitive products.

The user-friendly control panel allows operators to easily adjust settings for different container sizes and fill quantities.

Compact and efficient, this machine integrates seamlessly into smaller production setups, saving space and operational cost.

Half Pneumatic Auger Filler Machine

Half Pneumatic Auger Filler Machine for Semi-Automatic Accurate Filling Solutions

The Half Pneumatic Auger Filler Machine is a reliable and cost-effective solution for semi-automatic filling operations.

Designed for precision, it handles a wide range of materials, including powders, granules, and semi-solids, making it ideal for industries such as food, pharmaceuticals, and chemicals.

The pneumatic system ensures smooth and consistent operation, reducing manual effort while maintaining accuracy.

Its stainless-steel construction guarantees durability and hygiene compliance, suitable for sensitive products.

The user-friendly control panel allows operators to easily adjust settings for different container sizes and fill quantities.

Compact and efficient, this machine integrates seamlessly into smaller production setups, saving space and operational cost.

Product Specification

Filling Type: Semi-Automatic Auger Filler with Pneumatic Assistance

Filling Range: 10 gm to 500 gm (adjustable with interchangeable auger screw sizes)

Filling Speed: Up to 20-40 pouch per minute (depending on product and operator efficiency)

Filling Accuracy: ±1-2% (depending on product type and calibration)

Product Compatibility:

Powders: Flour, spices, milk powder, pharmaceutical powders, protein powder, coffee, etc.

Semi-Fine Granules: Detergent powder, chemical powders, etc.

Control Mechanism:

Pneumatic control for hopper gate and dispensing

Analog or Digital Timer for dosing

Hopper Capacity: 20-30 liters (customizable)

Power Supply: 220V, 50/60 Hz, Single-phase

Power Consumption: Approx. 1-2 kW

Air Pressure Requirement: 4-6 Bar

Material Contact Parts: Stainless Steel (SS304/SS316 for food-grade applications)

Discharge Mechanism: Auger screw-driven dispensing with pneumatic-controlled gates

Machine Dimensions: L x W x H (1200 mm x 800 mm x 1500 mm)

Weight: Approx. 250-300 kg