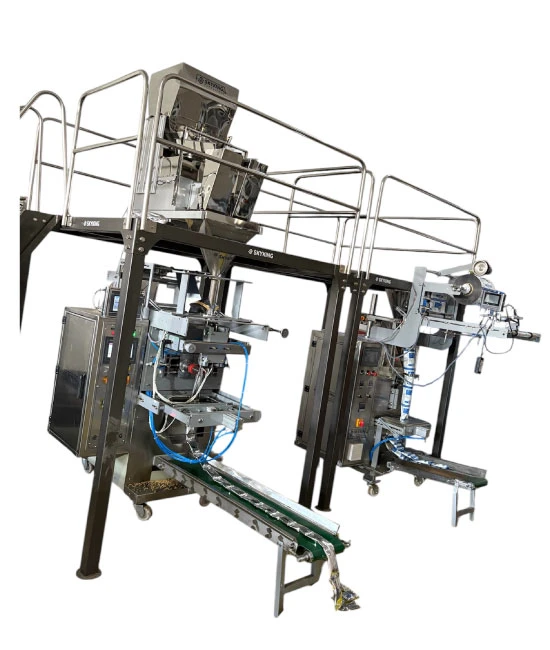

Fully Pneumatic 4 Head Weigher Filler Machine

Fully Pneumatic 4-Head Weigher Filler Machine for High-Speed Precision Filling

The Fully Pneumatic 4-Head Weigher Filler Machine is a premium solution for fast, accurate, and efficient filling operations.

Designed with four advanced pneumatic weighing heads, it allows simultaneous and precise filling of multiple units, significantly enhancing productivity.

Its robust stainless-steel construction ensures durability and adherence to hygiene standards, making it ideal for industries like food, pharmaceuticals, chemicals, and cosmetics.

The fully pneumatic operation minimizes electrical dependencies, offering smooth and reliable performance even in demanding environments.

With an intuitive control system, operators can easily adjust settings for different product types and weights, ensuring versatility for powders, granules, and small items.

Fully Pneumatic 4 Head Weigher Filler Machine

Fully Pneumatic 4-Head Weigher Filler Machine for High-Speed Precision Filling

The Fully Pneumatic 4-Head Weigher Filler Machine is a premium solution for fast, accurate, and efficient filling operations.

Designed with four advanced pneumatic weighing heads, it allows simultaneous and precise filling of multiple units, significantly enhancing productivity.

Its robust stainless-steel construction ensures durability and adherence to hygiene standards, making it ideal for industries like food, pharmaceuticals, chemicals, and cosmetics.

The fully pneumatic operation minimizes electrical dependencies, offering smooth and reliable performance even in demanding environments.

With an intuitive control system, operators can easily adjust settings for different product types and weights, ensuring versatility for powders, granules, and small items.

Product Specification

Filling Type: Fully Pneumatic Multi-Head Weigher (4 Heads)

Filling Range: 10 gm to 1 kg (adjustable as per product requirements)

Filling Speed: Up to 60-80 fills per minute (depending on product and weight per fill)

Accuracy: ±0.5-1% (depending on the product and calibration)

Hopper Capacity: 30-50 kg per head

Product Compatibility: Granules, powders, snacks, dry fruits, grains, pulses, tea, coffee, seeds, and similar products

Weighing Mechanism:

Individual load cells for each head

High-precision pneumatic actuators

Discharge Mechanism: Pneumatically controlled discharge gates

Control System:

PLC with HMI (Touchscreen Interface)

Multiple recipe memory for different product configurations

Air Pressure Requirement: 6-8 Bar

Power Supply: 220V/380V, 50/60 Hz, 3-phase

Power Consumption: Approx. 4-6 kW

Material Contact Parts: Stainless Steel (SS304/SS316 for food-grade safety)

Sealing Compatibility: Works with Form-Fill-Seal (FFS) machines or standalone sealing units

Conveyor System:

Infeed and outfeed conveyors

Adjustable speed

Machine Dimensions: L x W x H (3000 mm x 1500 mm x 2500 mm)

Weight: Approx. 1200-1500 kg

Temperature Control (Optional): Adjustable up to 300°C for sealing integration