Fully Automatic Cup Filler Machine

Fully Automatic Cup Filler Machine for Accurate and Efficient Filling Solutions

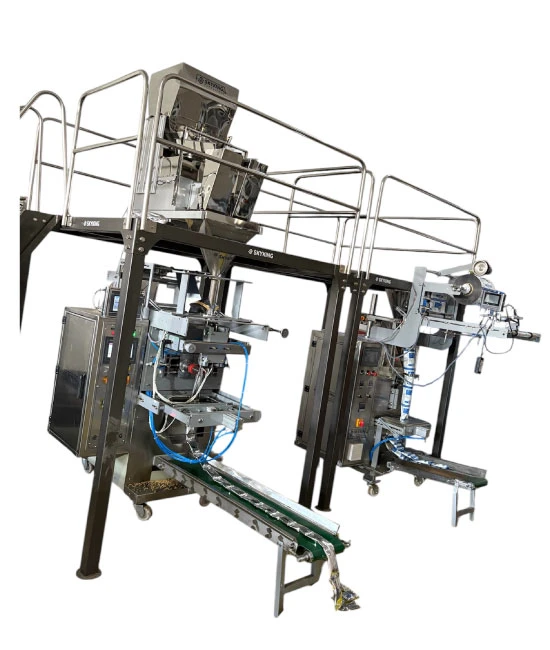

The Fully Automatic Cup Filler Machine is a state-of-the-art solution for precise and efficient filling of cups with liquids, powders, or granules.

Designed for versatility, it caters to various industries, including food, beverages, pharmaceuticals, and cosmetics. This machine automates the filling process, ensuring consistent accuracy and minimizing wastage.

With its robust stainless-steel construction, it offers durability and compliance with hygiene standards.

The intuitive control panel enables easy operation, while adjustable settings accommodate different cup sizes and fill quantities.

High-speed performance boosts productivity, making it ideal for large-scale production lines.

Equipped with advanced sealing mechanisms, it ensures leak-proof and tamper-evident packaging.

The compact design saves space, and its low maintenance requirements reduce downtime and operational use.

Fully Automatic Cup Filler Machine

Fully Automatic Cup Filler Machine for Accurate and Efficient Filling Solutions

The Fully Automatic Cup Filler Machine is a state-of-the-art solution for precise and efficient filling of cups with liquids, powders, or granules.

Designed for versatility, it caters to various industries, including food, beverages, pharmaceuticals, and cosmetics. This machine automates the filling process, ensuring consistent accuracy and minimizing wastage.

With its robust stainless-steel construction, it offers durability and compliance with hygiene standards.

The intuitive control panel enables easy operation, while adjustable settings accommodate different cup sizes and fill quantities.

High-speed performance boosts productivity, making it ideal for large-scale production lines.

Equipped with advanced sealing mechanisms, it ensures leak-proof and tamper-evident packaging.

The compact design saves space, and its low maintenance requirements reduce downtime and operational use.

Product Specification

Filling Type: Volumetric Cup Filler (Suitable for granular or free-flowing products)

Filling Capacity: 50 g to 1 kg (customizable based on requirements)

Filling Speed: Up to 30-60 Pouch per minute (depending on product type and cup size)

Accuracy: ±1-2% (depending on the product and calibration)

Machine Dimensions: L x W x H (3000 mm x 1200 mm x 2000 mm)

Hopper Capacity: 30-50 kg (customizable)

Cup Diameter: 50 mm to 120 mm (adjustable)

Cup Height: Up to 150 mm (adjustable)

Power Supply: 220V/380V, 50/60 Hz, 3-phase

Power Consumption: Approx. 3-5 kW

Control System: PLC with HMI (Touch Screen Interface)

Material Contact Parts: Stainless Steel (SS304 or SS316)

Air Pressure Requirement: 6-8 Bar

Conveyor Type: Adjustable belt or chain conveyor

Film Material for Sealing: Heat-sealable laminates, such as PET, BOPP, or aluminum foil

Sealing Mechanism: Heat sealing or ultrasonic sealing (optional)

Temperature Control: Digital, adjustable up to 300°C