Fully Pneumatic Auger Filler Machine With Servo

Fully Pneumatic Auger Filler Machine with Servo for Precise Filling Solution

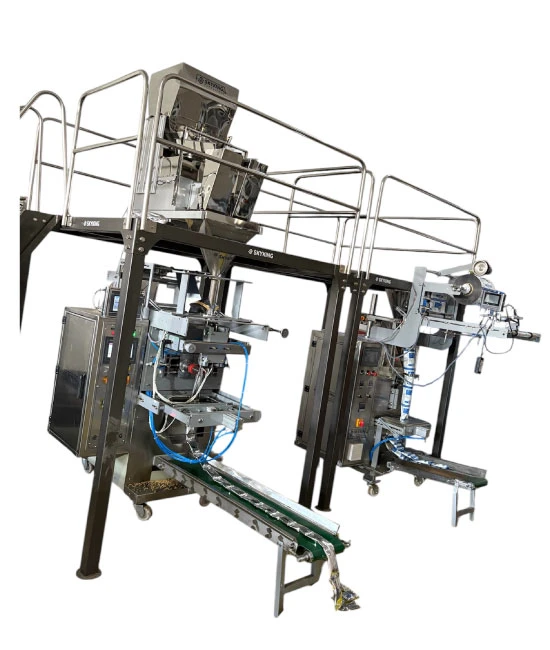

The Fully Pneumatic Auger Filler Machine with Servo is a high-precision filling solution designed to handle a variety of materials, including powders, granules, and semi-solids.

Combining pneumatic functionality with servo-driven accuracy, this machine delivers consistent and efficient filling for industries such as food, pharmaceuticals, and cosmetics.

Its advanced servo motor technology ensures precise weight control and smooth operation, while the robust pneumatic system enhances reliability.

Made from durable stainless steel, it meets hygiene standard and withstands rigorous industrial use.

The intuitive control panel enables easy setup and operation, with adjustable settings to accommodate various container sizes and fill volumes.

Its compact design optimizes floor space, making it a perfect addition to existing production lines.

Fully Pneumatic Auger Filler Machine With Servo

Fully Pneumatic Auger Filler Machine with Servo for Precise Filling Solution

The Fully Pneumatic Auger Filler Machine with Servo is a high-precision filling solution designed to handle a variety of materials, including powders, granules, and semi-solids.

Combining pneumatic functionality with servo-driven accuracy, this machine delivers consistent and efficient filling for industries such as food, pharmaceuticals, and cosmetics.

Its advanced servo motor technology ensures precise weight control and smooth operation, while the robust pneumatic system enhances reliability.

Made from durable stainless steel, it meets hygiene standard and withstands rigorous industrial use.

The intuitive control panel enables easy setup and operation, with adjustable settings to accommodate various container sizes and fill volumes.

Its compact design optimizes floor space, making it a perfect addition to existing production lines.

Product Specification

Filling Type: Auger Filler with Servo Motor Control

Filling Range: 10 gm to 1 kg (adjustable as per product requirements)

Filling Speed: Up to 30-50 fills per minute (depending on product flow and weight per fill)

Filling Accuracy: ±0.5% (depending on the product and calibration)

Product Compatibility:

Powders: Flour, spices, milk powder, pharmaceutical powders, protein powder, etc.

Semi-Fine Granules: Coffee powder, detergents, etc.

Control Mechanism:

PLC with HMI (Touchscreen Interface)

Servo motor for precise auger rotation

Pneumatic components for machine movements

Hopper Capacity: 30-50 liters (customizable based on requirements)

Power Supply: 220V/380V, 50/60 Hz, 3-phase

Power Consumption: Approx. 3-5 kW

Air Pressure Requirement: 6-8 Bar

Material Contact Parts: Stainless Steel (SS304/SS316 for food-grade applications)

Discharge Mechanism:

Auger-controlled dispensing

Pneumatically operated gates for additional control

Machine Dimensions: L x W x H (1800 mm x 1200 mm x 2000 mm)

Weight: Approx. 600-800 kg

Sealing Compatibility: Works with form-fill-seal machines, jar filling systems, or bottle packaging lines

Temperature Control (Optional): Adjustable for integrated sealing systems