2025’S Top Manual Bottle Packing Machines In India – Compare Features & Reviews

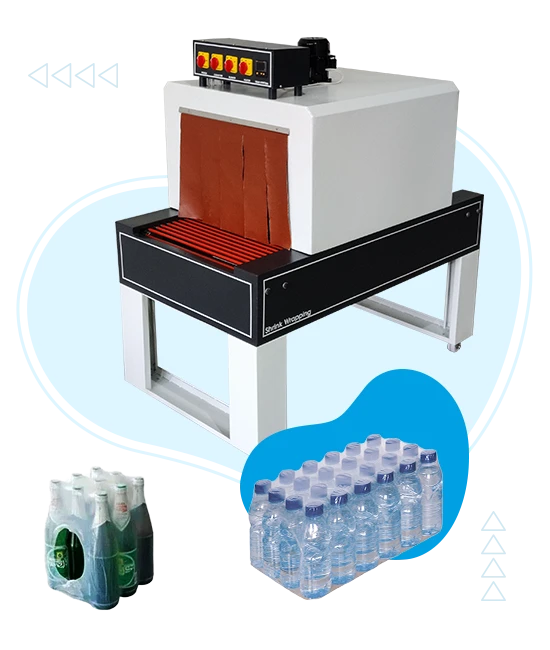

Manual Bottle Packing Machines continue to be a preferred choice for small to medium-scale businesses in India that require cost-effective and reliable packaging solutions.

These machines are designed for easy operation, allowing workers to manually place bottles while the machine ensures proper sealing, labeling, or wrapping with consistent results.

In 2025, the demand for manual bottle packing machines has increased due to their affordability, low maintenance requirements, and ability to handle different types and sizes of bottles. They are particularly useful for industries such as beverages, water plants, edible oils, cosmetics, and pharmaceuticals where small-scale packaging plays a vital role.

One of the biggest advantages of these machines is their durability and long service life, as they are built with sturdy materials that can withstand continuous use.

They also help businesses save on electricity and labor costs compared to fully automatic machines, making them a smart investment for startups and regional producers. Easy portability and compact designs allow them to fit into limited spaces without requiring large factory setups.

Customers across India appreciate manual bottle packing machines for their simplicity, consistency, and ability to deliver professional packaging results without heavy expenses.

By comparing features and reviews of 2025’s top models, businesses can identify the best machine that suits their production needs, budget, and future growth plans, ensuring smooth and efficient operations in the competitive packaging industry.